Predetermined Overhead Rate Formula, Explanation and Example

Moreover, regularly reviewing and adjusting the predetermined overhead rate can help businesses adapt to changes in their cost structure or operations, ensuring they remain competitive and profitable. The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period. Take, for instance, a manufacturing company that produces gadgets; the production process of the gadgets would require raw material inputs and direct labor. These two factors would definitely make up part of the cost of producing each gadget. In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate. For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process.

- In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate.

- Predetermined overhead is an estimated rate used by the business to absorb overheads in the product cost, and it’s calculated by dividing overheads by the budgeted level of activity.

- Businesses normally face fluctuation in product demand due to seasonal variations.

- In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine hours, as the single activity.

- Here, the estimated overhead costs include all indirect costs related to production, such as rent, utilities, and depreciation.

- This base should be a measure of activity that correlates with the incurrence of overhead costs.

Sales and production decisions based on this rate could be faulty

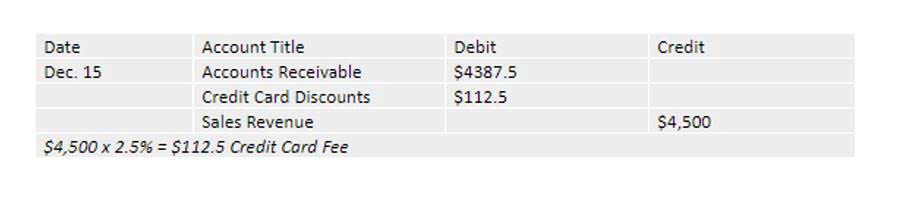

The applied overhead is then added to the product’s direct material and direct labor costs to determine its total manufacturing cost. A predetermined overhead rate is calculated at the start of the accounting period by dividing the estimated manufacturing overhead by the estimated activity base. The predetermined overhead rate is then applied to production to facilitate determining a standard cost for a product. The predetermined overhead rate allocates estimated total overhead for an accounting period across expected activity or production volume. It is calculated before the period begins and is used to assign overhead costs to production using an allocation rate per unit of activity, such as direct labor hours. A predetermined overhead rate assigns indirect manufacturing costs to products or services in cost a predetermined overhead rate includes accounting.

- A number of possible allocation bases are available for the denominator, such as direct labor hours, direct labor dollars, and machine hours.

- This allocation process depends on the use of a cost driver, which drives the production activity’s cost.

- Implementation of ABC requires identification and record maintenance for various overheads.

- This predetermined overhead rate can also be used to help the marketing agency estimate its margin on a project.

Best Practices for Overhead Rate Management

This variance is adjusted in financial statements, often through cost of goods sold (COGS). For the past 52 years, Harold Averkamp (CPA, MBA) hasworked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. For the past 52 years, Harold Averkamp (CPA, MBA) has worked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. If you’d like to learn bookkeeping more about calculating rates, check out our in-depth interview with Madison Boehm.

Applications of Predetermined Overhead Rates

As a result, management would likely view labor hours as the activity base when applying overhead costs. Overhead costs are indirect expenses incurred during manufacturing or service delivery, untraceable to a specific product or service. These are distinct from direct costs, such as raw materials and direct labor, which are directly involved in production. Albert Shoes Company calculates its predetermined overhead rate on the basis of annual direct labor hours.

Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs. This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead costs incurred. The consistent application of overhead is valuable for inventory valuation, as U.S. Generally Accepted Accounting Principles (U.S. GAAP) require all manufacturing costs—direct materials, direct labor, and overhead—to be assigned to products for inventory costing. This ensures work-in-process and finished goods inventory are reported at full absorption cost on financial statements.

Calculation

The predetermined overhead rate formula is calculated by dividing the total estimated overhead costs for the period by the estimated activity base. A later analysis reveals that the actual amount that should have been assigned to inventory is $48,000, so the $2,000 difference is charged to the cost of goods sold. Since the predetermined overhead rate relies on estimated figures, the total https://kaos.simplecarta.com/2023/04/17/6-4-the-basic-accounting-for-contributions/ amount of overhead applied to production during an accounting period will rarely exactly match the actual overhead costs incurred. This difference leads to either “underapplied overhead” or “overapplied overhead.” Underapplied overhead occurs when actual overhead costs are greater than the overhead applied to production. Conversely, overapplied overhead arises when actual overhead costs are less than the amount applied. Consider a manufacturing company that expects to incur $120,000 in overhead costs during a production period.

Methods of Selecting an Activity Base

- Although it has limitations, its benefits in budgeting, pricing, and efficiency make it an essential component of managerial accounting.

- That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty.

- Now, let’s look at some hypothetical business models to see actual use-cases for predetermined overhead rates.

- For the past 52 years, Harold Averkamp (CPA, MBA) hasworked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online.

- When there is a big difference between the actual and estimated overheads, unexpected expenses will definitely be incurred.

- The predetermined rate is also used for preparing budgets and estimating jobs costs for future projects.

Suppose GX company uses direct labor hours to assign manufacturing overhead cost to job orders. The company’s budget shows an estimated manufacturing overhead cost of $16,000 for the forthcoming year. The company estimates that 4,000 direct labors hours will be worked in the forthcoming year. The production manager has told us that the manufacturing overhead will be $ 500,000 for the whole year and the company expected to spend 20,000 hours on direct labor. The management concern about how to find a predetermined overhead rate for costing. This estimated rate helps in valuing inventory and making prompt pricing decisions.